The Beginning Challenges

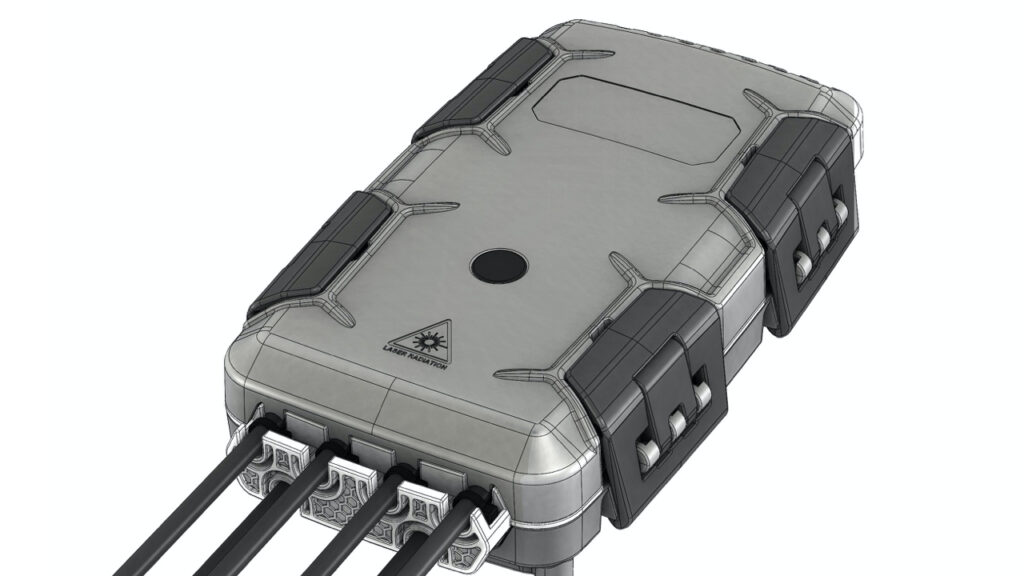

PIMMS Group design division, then known as KM Product Design, were called on by 7Twenty in 2018 to help it design a MicroLoop enclosure that was rugged and robust enough to withstand the FTTx mass deployment requirements with the focus on speed of deployment in the fibre installation process. It needed to be a non-metallic enclosure to avoid rust, specifically for coastal regions. It also needed to be suitable for wall mounting as well as placement inside underground chambers, making it waterproof to an IP68 rating.

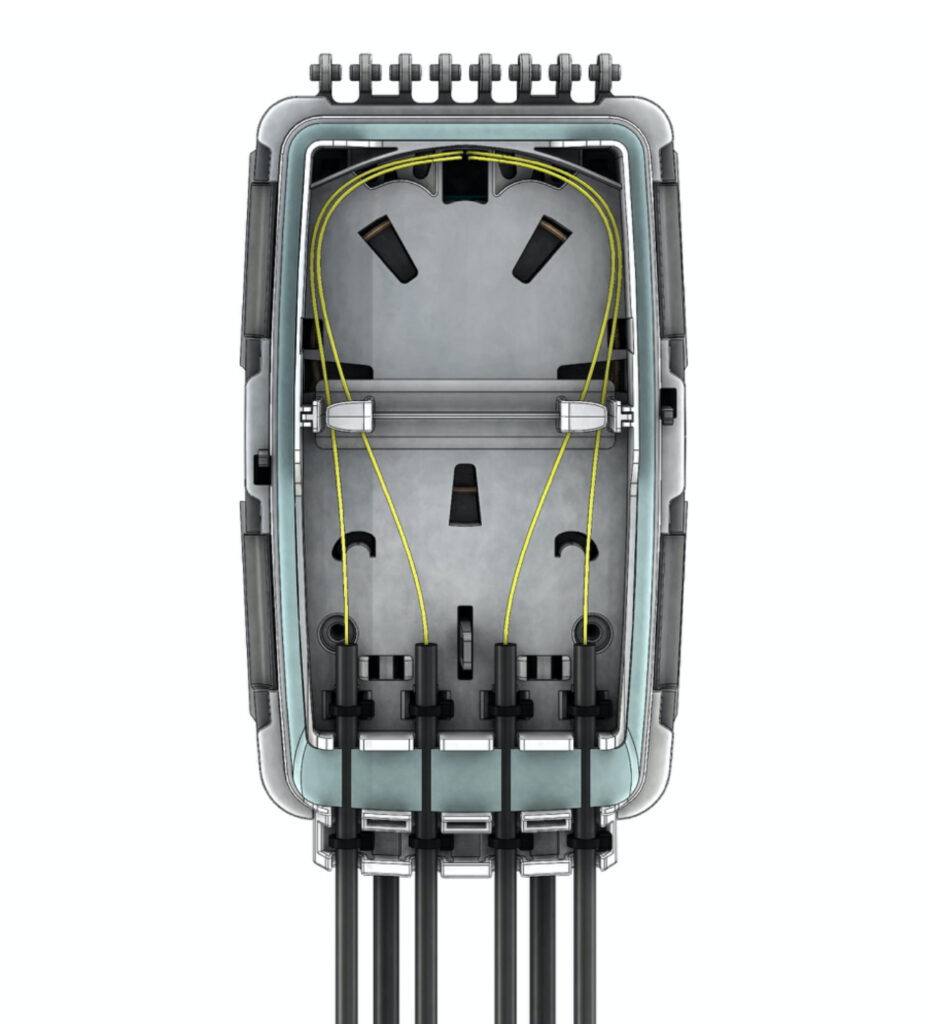

Part of the complicated brief was to make it equipped for mid-span access with integrated bare fibre loop storage and facilitate up to 4 drop cables either preconnectorized or spliced. The design team and I were more than ready for the challenge and applied a user-centered approach throughout the development process.

The biggest challenge was the sealing configuration, to allow pre-connectorized drop cables to be inserted without compromising the seal or the use of complicated additional sealing components.

User Friendly for Technicians

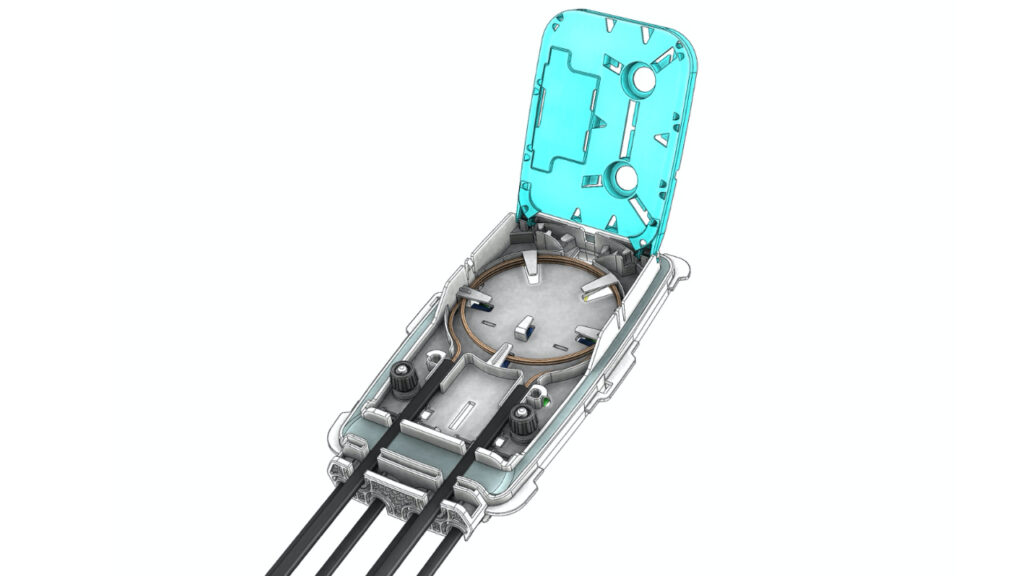

A major point from the brief of the MicroLoop was to make it extremely user friendly for the technicians. And as mentioned before, this helps speed up deployment. The inner cable assembly is fully removable allowing ease of access and convenience for the technician to work with, outside of its housing. This makes for a much easier and speedier installation/repair of the network. We designed it so that the enclosure’s lid opens upward and contains a self-supporting hinge to allow the lid to remain in the open position while accessing the inner cable assembly

Splice Tray

The splice tray hinges upwards and remains in position allowing unhindered access to the loop storage tray. Once the splice tray is returned to the resting point, there are two clips securing the tray in place.

Fantastic Result

We designed this over a period of approximately 6 months and 7Twenty were extremely pleased with the outcome. We more than exceeded their expectations and we crushed the waterproofing brief as we were able to IP test the enclosure at 1 metre head of water for 30 minutes.

The mould was developed by PIMMS Group tooling division and the product went into production at PIMMS Group. This enclosure is successfully utilised throughout Southern Africa in the installation of passive fibre optics networks.